Row Cleaner Module Setup

Find important steps to set up Row Cleaner Module.

Updated March 11, 2021

Row Cleaner Module Setup

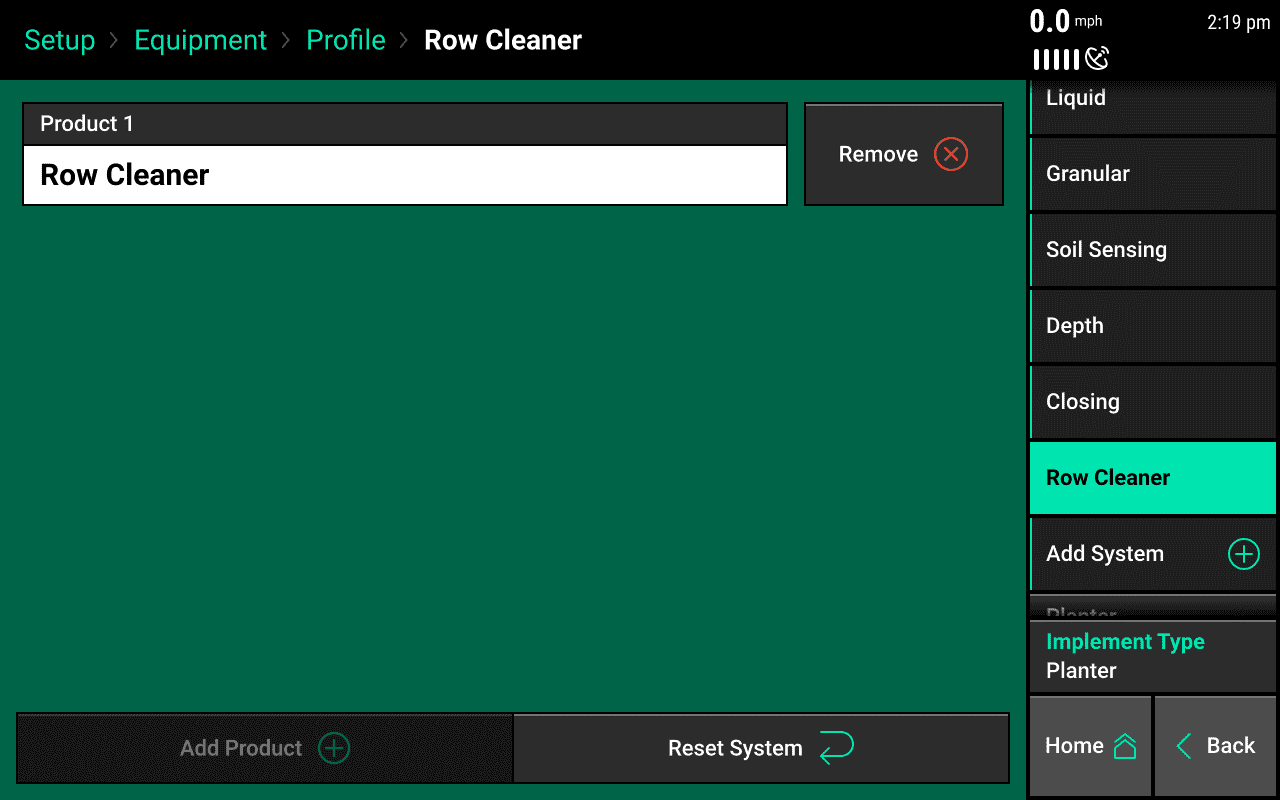

To begin configuring the monitor for the Row Cleaner Module, navigate on the monitor to Setup > Equipment > Add System and select Row Cleaner. Add Row Cleaner as Product 1.

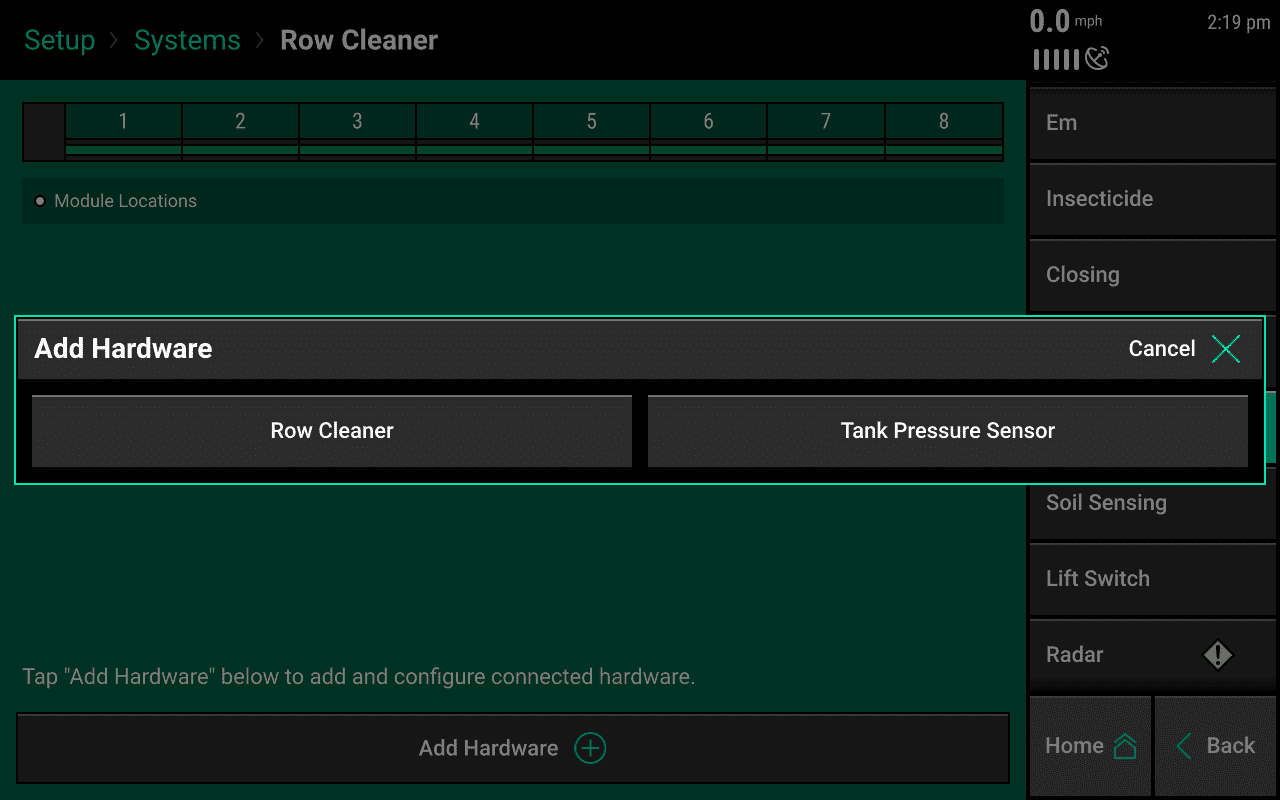

Add Hardware - Row Cleaner Module

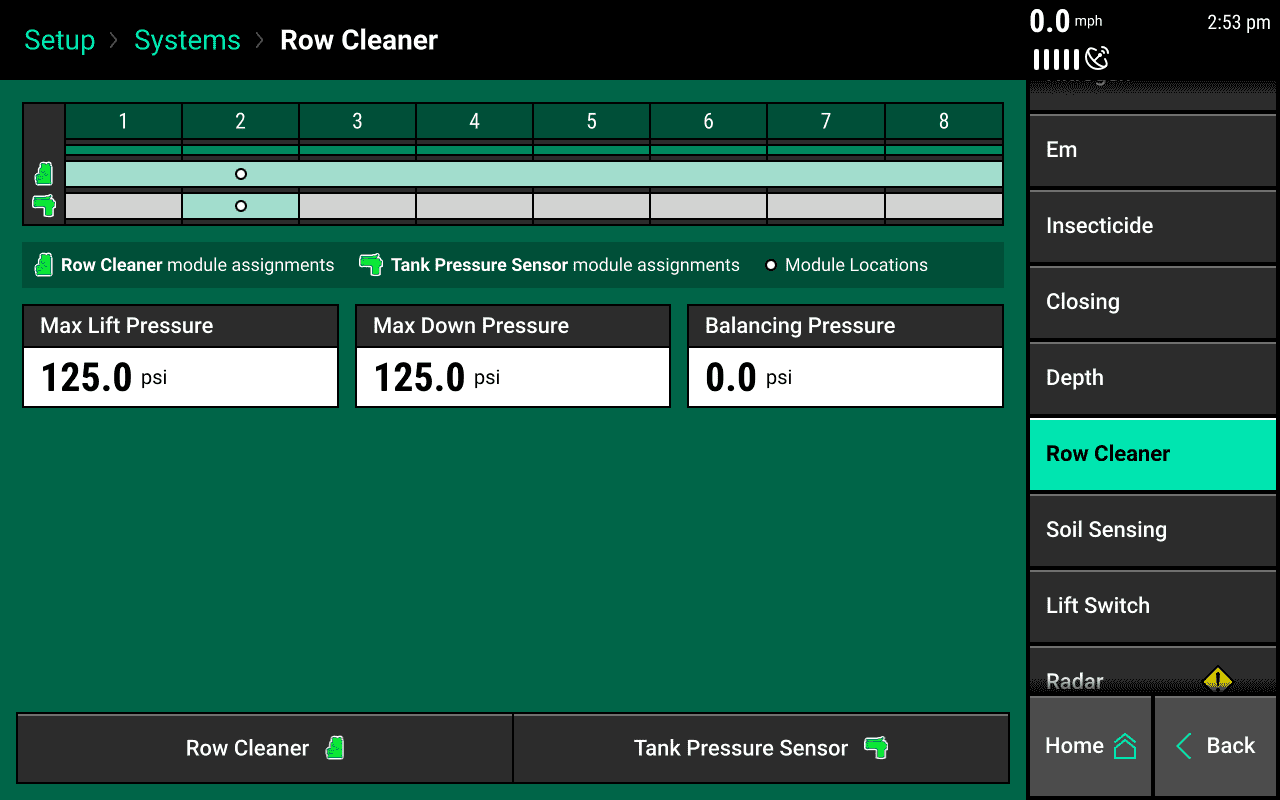

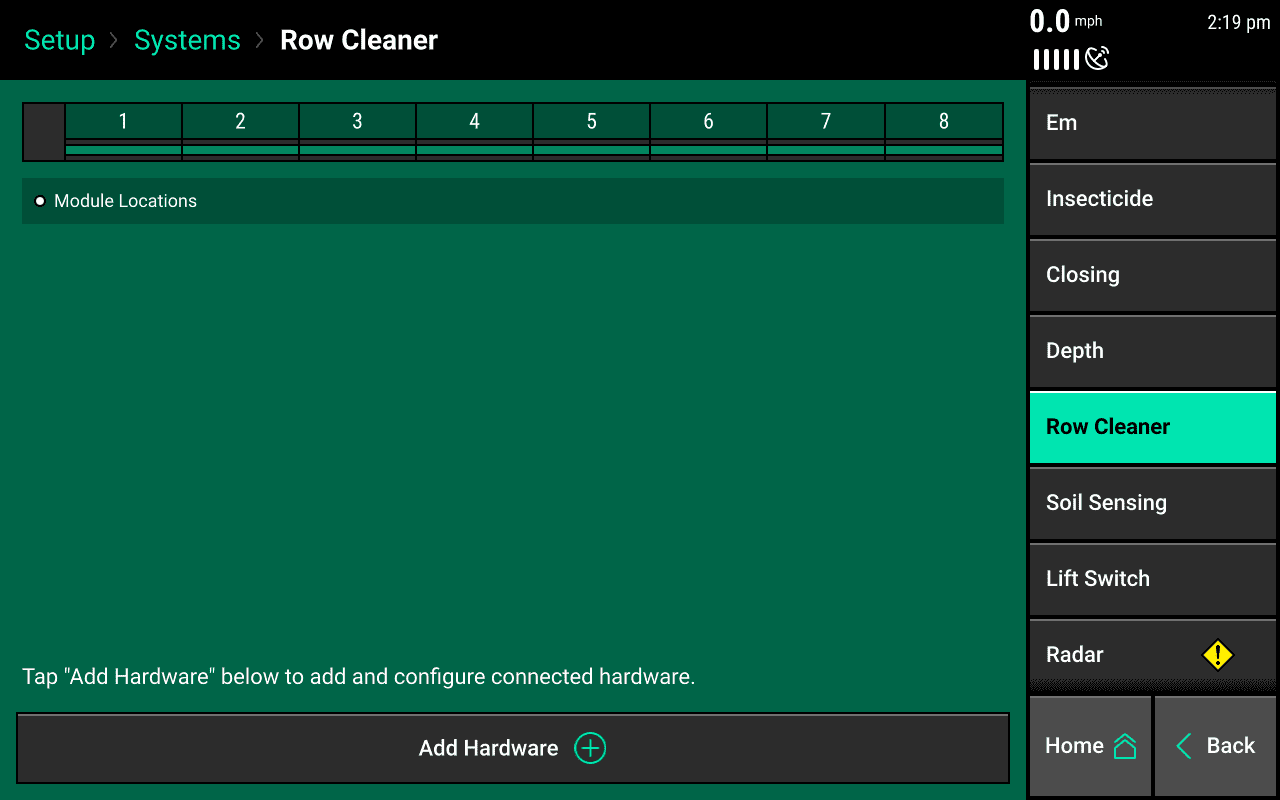

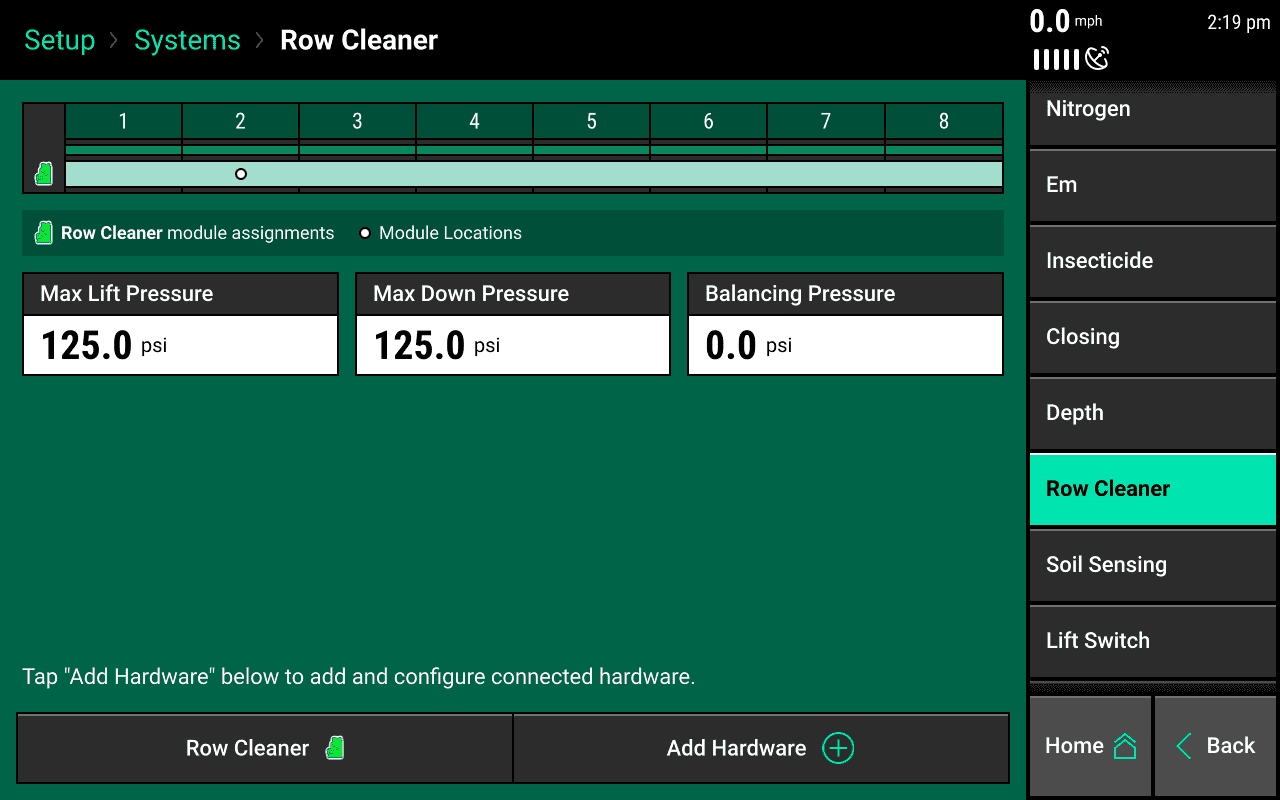

Once the Row Cleaner System has been added to the Equipment Profile, a Row Cleaner tab will appear on the systems tab. Go to Setup > Systems > Row Cleaner to configure the Row Cleaner Module.

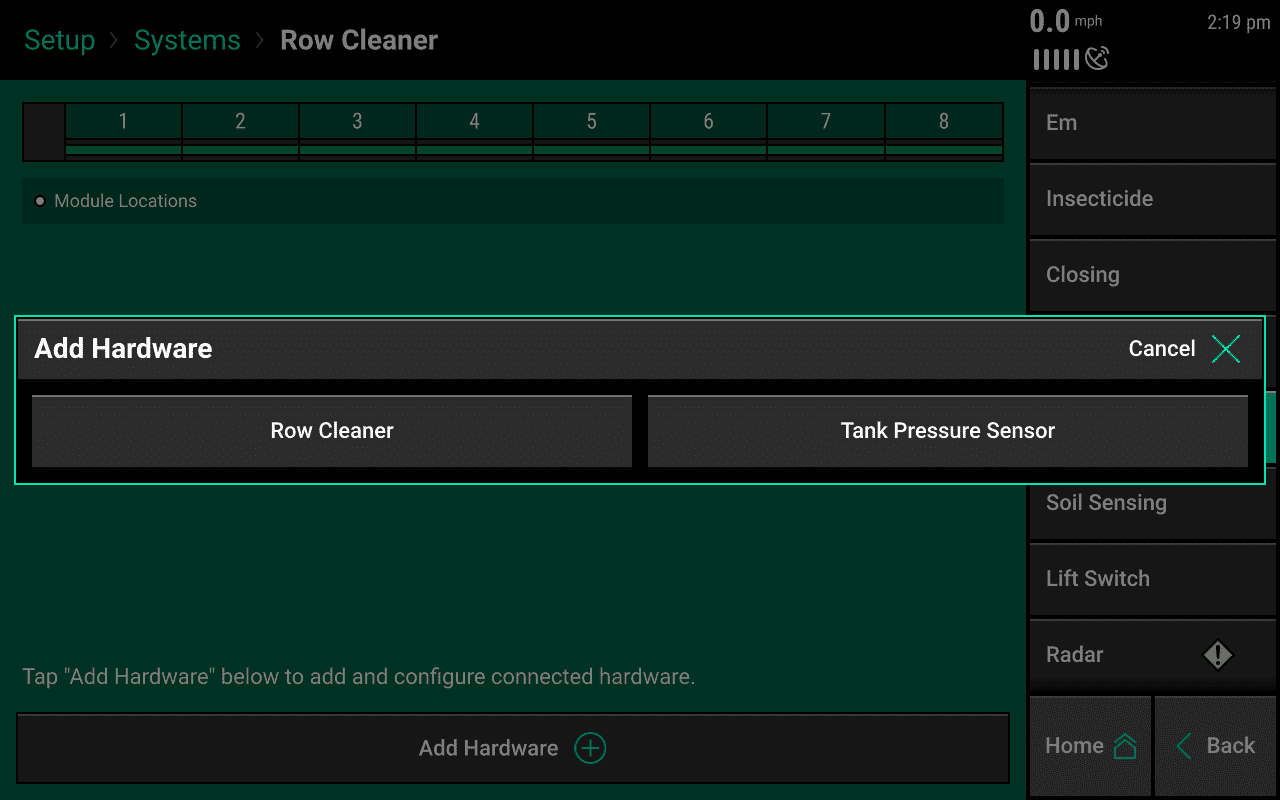

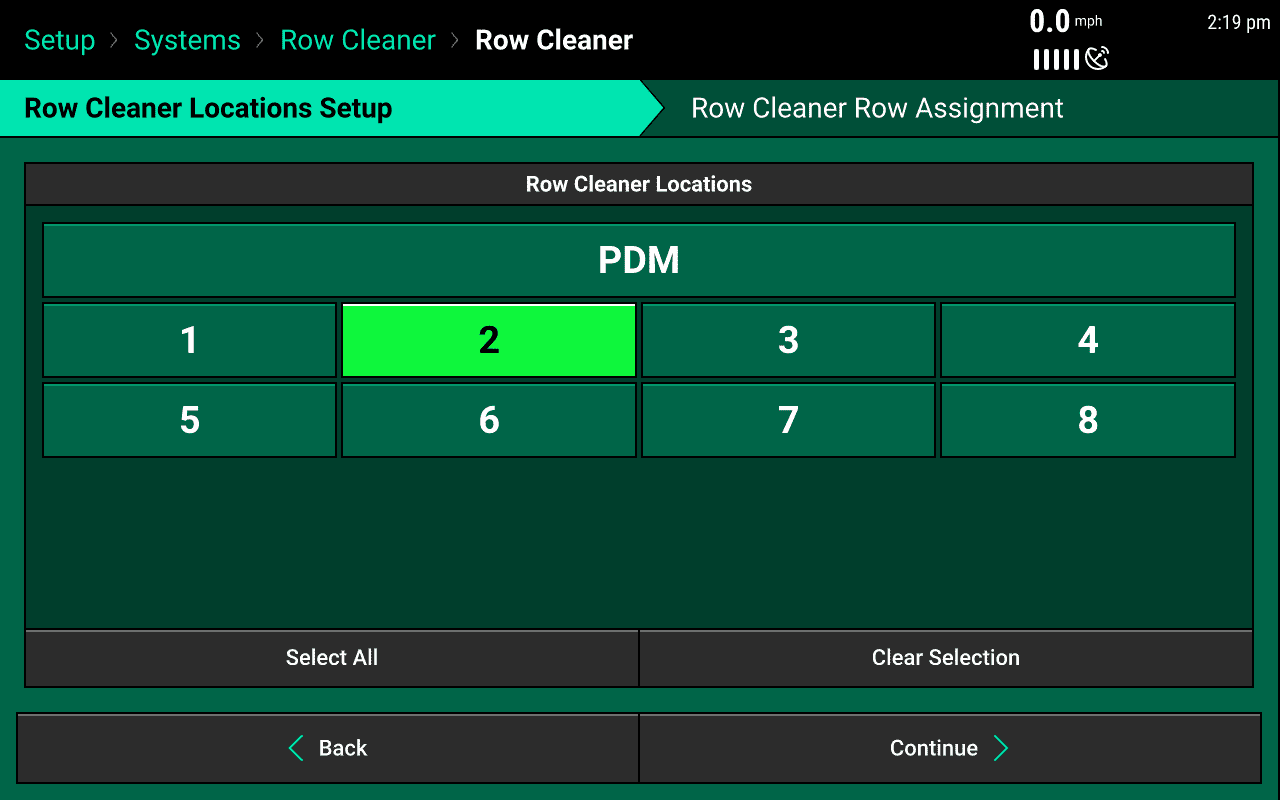

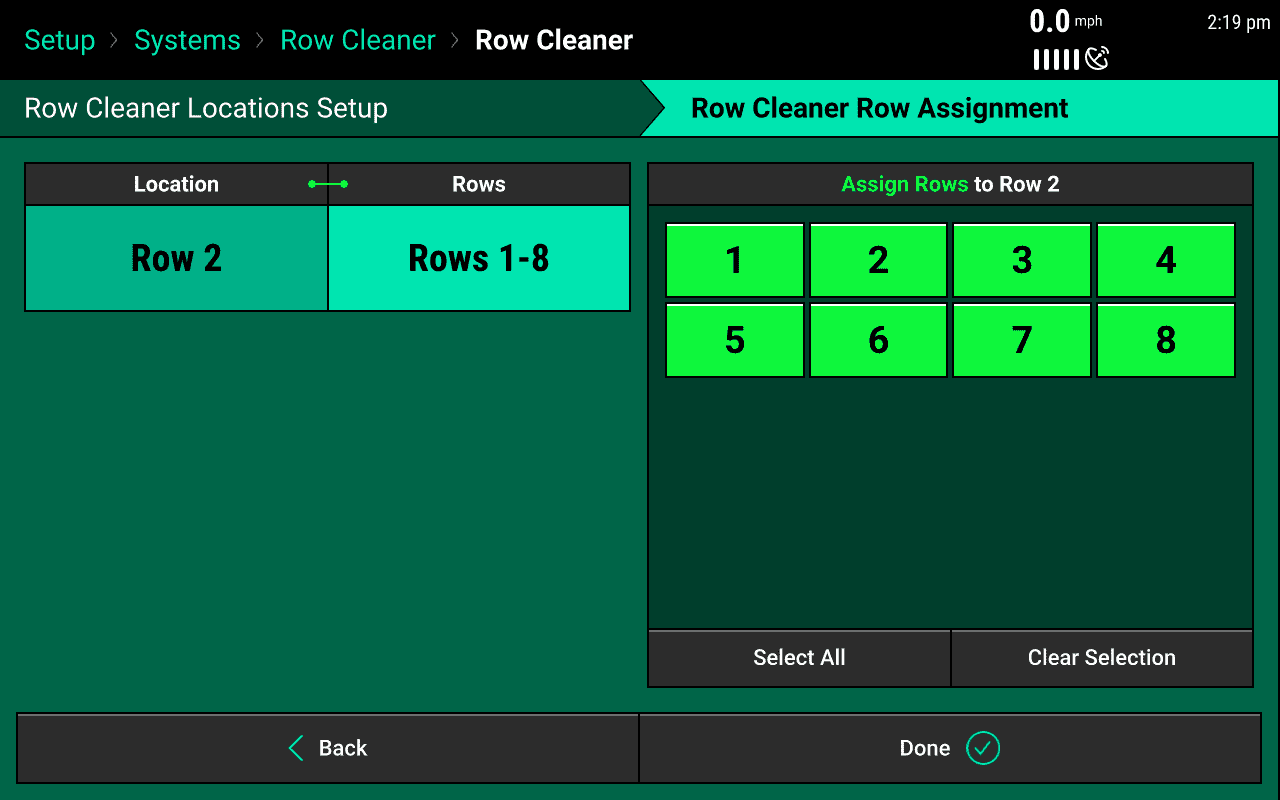

Use the ‘Add Hardware’ button at the bottom of this page to assign which rows have the Row Cleaner Module installed.

Max Lift Pressure — The default value is 125 psi. Adjusting this will change the max lift pressure the row cleaner control module will adjust to.

Max Down Pressure — The default value is 125 psi. Adjusting this will change the max down pressure the row cleaner control module will adjust to.

Balancing Pressure — Balancing pressure is used to apply an (initial) equal pressure to both the lift and down circuit, if desired. If the balancing pressure is set, the control target setting (lift or down) will apply pressure appropriately to overcome the balancing pressure. For example, if the balancing pressure is set to 10 psi and then the control target is set to 10 psi lift, the lift circuit will have 20 psi and the down circuit will have 10 psi.

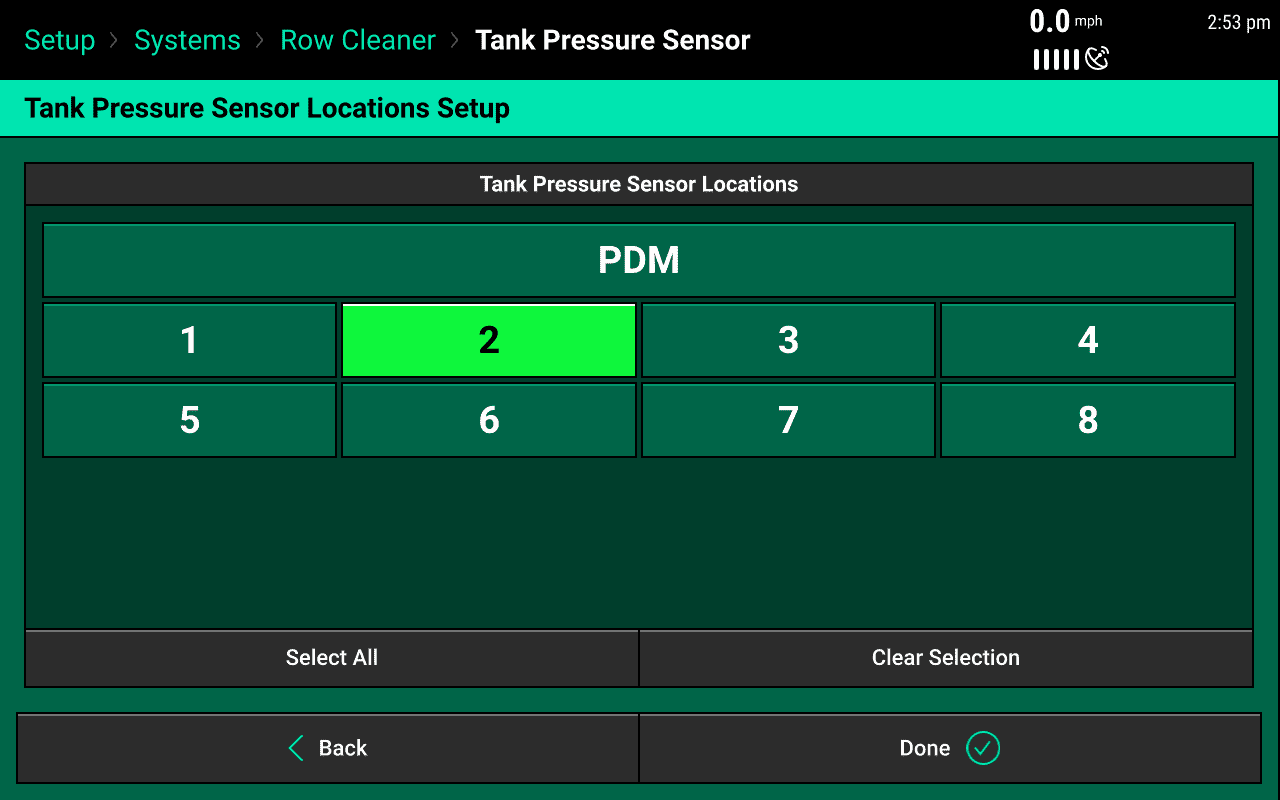

Add Hardware - Tank Pressure Sensor

Once the Row Cleaner Module has been added, a Tank Pressure Sensor can be added to monitor the Row Cleaner tank pressure. Go to Setup > Systems > Row Cleaner to configure the Tank Pressure Sensor.

Use the ‘Add Hardware’ button at the bottom of this page to assign which rows have a Tank Pressure Sensor installed.